Railway Electrification Systems by S Frey. Figure 1: A section of the Old Dalby take a look at observe in England showing each third rail and overhead electrification. Figure 3: Docklands Light Railway train with 3rd rail backside contact electrification system. This diagram reveals a DC 3-Rail Traction System with the situation of the present rail in relation to the running rails. There’s a large variety of electric traction techniques all over the world and these have been constructed in response to the type of railway, its location and the expertise available on the time of the installation. Because the changes have been so rapid, there are nonetheless plenty of examples of the original expertise around and in common use, so I’ve coated these in my articles. COLLECTOR’S NOTES: Certain details of this digital camera underwent minor adjustments throughout the overall manufacturing run. What had been the accepted norms for the business for sometimes, eighty years, have all of a sudden been thrown out and replaced by fundamental changes in design, manufacture and operation. The third rail system makes use of a “shoe” to collect the present on the train, maybe as a result of it was first referred to as a “slipper” by the pioneers of the industry (it slipped along the rail, Ok?) but it was not very fairly to have a look at, so perhaps somebody thought shoe was a greater description.

Railway Electrification Systems by S Frey. Figure 1: A section of the Old Dalby take a look at observe in England showing each third rail and overhead electrification. Figure 3: Docklands Light Railway train with 3rd rail backside contact electrification system. This diagram reveals a DC 3-Rail Traction System with the situation of the present rail in relation to the running rails. There’s a large variety of electric traction techniques all over the world and these have been constructed in response to the type of railway, its location and the expertise available on the time of the installation. Because the changes have been so rapid, there are nonetheless plenty of examples of the original expertise around and in common use, so I’ve coated these in my articles. COLLECTOR’S NOTES: Certain details of this digital camera underwent minor adjustments throughout the overall manufacturing run. What had been the accepted norms for the business for sometimes, eighty years, have all of a sudden been thrown out and replaced by fundamental changes in design, manufacture and operation. The third rail system makes use of a “shoe” to collect the present on the train, maybe as a result of it was first referred to as a “slipper” by the pioneers of the industry (it slipped along the rail, Ok?) but it was not very fairly to have a look at, so perhaps somebody thought shoe was a greater description.

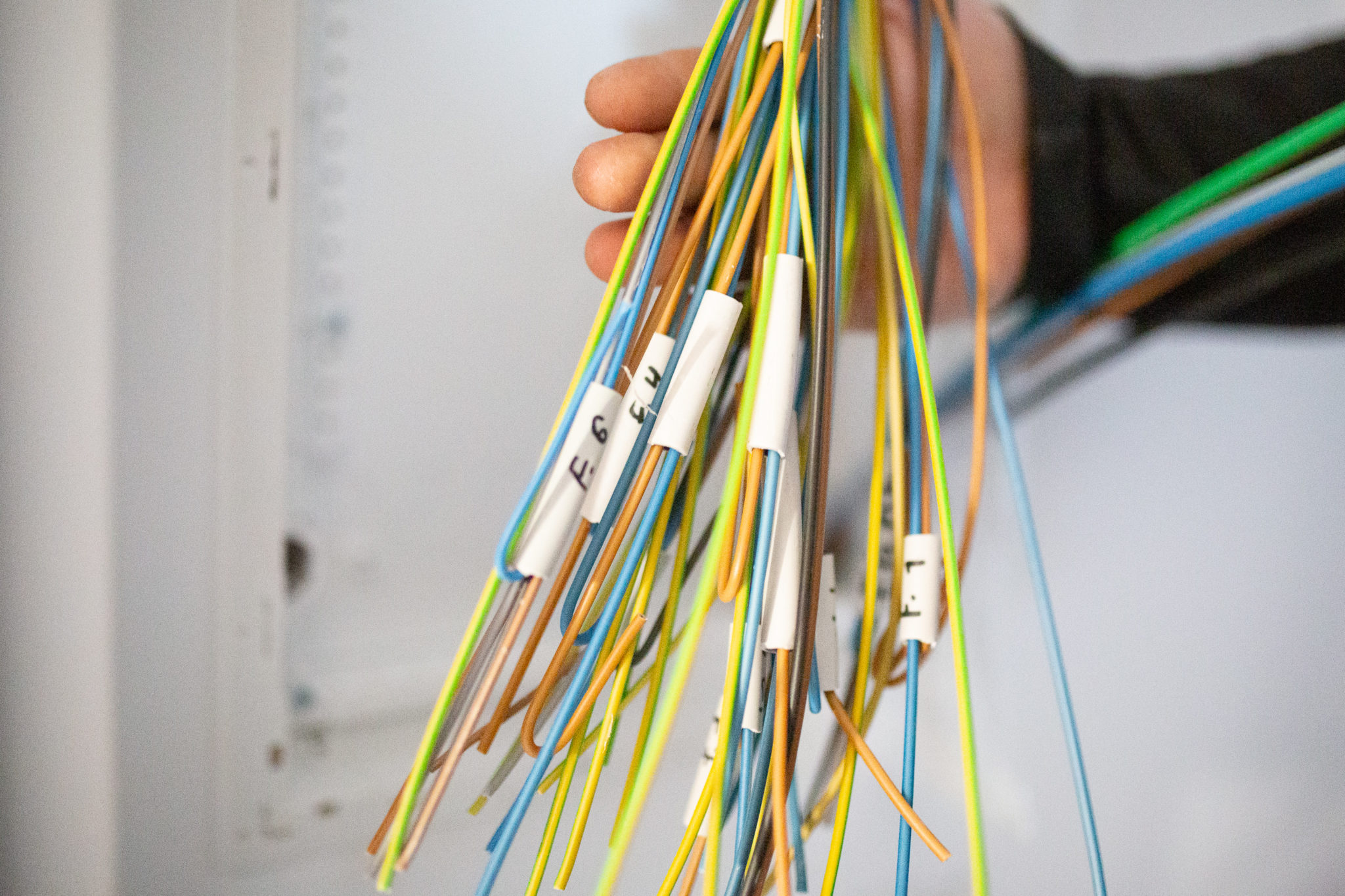

The 3rd rail system is frequent around the world however the 4th rail is uncommon. AC techniques all the time use overhead wires, DC can use either an overhead wire or a 3rd rail; both are widespread. The most common cause is when a shoe breaks off and its connecting result in the electrical gear on the prepare must be secured safely. The rear automotive is supplied through a 25 kV cable operating the length of the practice. Transmission of energy is all the time alongside the track by way of an overhead wire or at ground stage, using an additional, third rail laid close to the operating rails. The tendency of return currents to wander away from the operating rails into the bottom can set up electrolysis with water pipes and related metallics. A second set of magnets restores the ability instantly after the neutral part has been handed. Exposure set by Light Value scale. An instance of a backside contact shoe as used on the Dockland Light Railway line in London is proven in Figure 3 and in the video (Figure 5). Some high contact systems have also used spring loading but they’re mechanically tougher to control due to the hunting motion of the bogie and the chance that the sneakers will get trapped beneath the head of the rail and turn it over.

The 3rd rail system is frequent around the world however the 4th rail is uncommon. AC techniques all the time use overhead wires, DC can use either an overhead wire or a 3rd rail; both are widespread. The most common cause is when a shoe breaks off and its connecting result in the electrical gear on the prepare must be secured safely. The rear automotive is supplied through a 25 kV cable operating the length of the practice. Transmission of energy is all the time alongside the track by way of an overhead wire or at ground stage, using an additional, third rail laid close to the operating rails. The tendency of return currents to wander away from the operating rails into the bottom can set up electrolysis with water pipes and related metallics. A second set of magnets restores the ability instantly after the neutral part has been handed. Exposure set by Light Value scale. An instance of a backside contact shoe as used on the Dockland Light Railway line in London is proven in Figure 3 and in the video (Figure 5). Some high contact systems have also used spring loading but they’re mechanically tougher to control due to the hunting motion of the bogie and the chance that the sneakers will get trapped beneath the head of the rail and turn it over.

Figure 12: Russian video of a pantograph being damaged by an overhead wire out of place. Overhead current collectors use a “pantograph”, so known as as a result of that was the shape of most of them till about 30 years in the past. Many installations seen as we speak had been first constructed more than one hundred years ago, some when electric traction was barely out of its diapers, so to speak, and this has had an excellent affect on what is seen at present. Within the final 20 years there has been a rapid acceleration in railway traction growth. It will possibly use both DC (direct current) or AC (alternating current), the former being, for many years, easier for railway traction functions, the latter being higher over lengthy distances and cheaper to install but, till just lately, more difficult to manage at prepare degree. Both overhead methods require at the least one collector connected to the practice so it may possibly all the time be in touch with the facility.

Figure 2: A 3rd rail collector shoe on a suburban EMU in London. London Underground is the most important user of the 4-rail system in the world. Both techniques are supplied to permit train testing from the primary line or London Underground. More not too long ago, mechanical or pneumatic systems have been devised to make it possible to elevate sneakers from inside the practice remotely from the driving cab. The higher the speed, the more difficult the upkeep of fine contact. For the reason that pantograph is usually the only level power contact for the locomotive or power automobile, it must maintain good contact beneath all running conditions. These are turned downwards to reduce the danger of the pantograph being hooked excessive of the contact wire as the practice moves along. You’ll usually see trains with just one pantograph however, on trains which use shoes, there are always a number of footwear. Two contact faces are normally provided.